Be Water, My friend..

Our first irrigation project at Stella Porta

In my first article of this series, I talked about how one of the goals of our move to Arkansas was to set up a market garden we named Stella Porta Farms. Since the property was mainly used for running cattle, we had to create our crop irrigation system.

Fortunately, there were lots, and by lots, I mean about a mile of 2” waterline buried in the ground going from the well pump out to various cattle stations. We were even able to find a rough map of the system. So we did some rough reckoning and drew a line of site where we thought the pipe crossed at an advantageous place and got out old Mr. Shovel and dug. Soon enough, and with more luck than I care to admit, we found a PVC line a little more than a foot down.

I was very cautious about damaging the existing water system; part of it fed our domestic water. So, I hired a professional plumber to terminate a shut-off that I could work from.

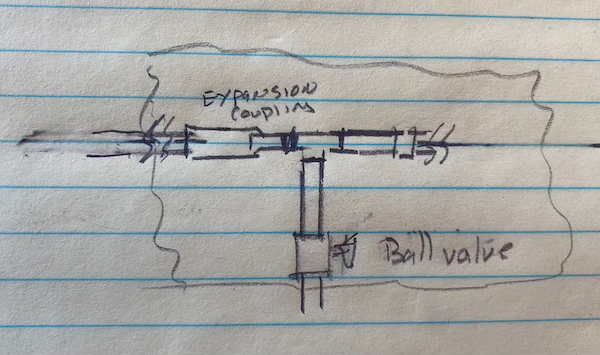

So, how do you intercept and make a T connection to an underground PVC line with minimal excavation? It turns out there is such a thing as an expansion repair coupling. This device is remarkable; it uses O-rings to make a leakproof splice.

From the T connection, the plumber hooked up a ball valve, and I took it from there. Since we intended to use drip irrigation tape on our crops, It was necessary to install a filter before transitioning to the crop irrigation line. I chose the 2” T super filter from Amaid Water Systems for this task. It was well-designed and rugged and allowed me to use a washable filter.

I dug a pair of posts in the ground, made a mounting system for the filter, and installed a flush valve before and after the filter to allow me to depressurize it for filter change and maintenance.

Next, we rented a Ditch Witch and carefully proceeded to dig trenches for our new irrigation lines. We already had crops in the ground in some places. We also made a place to tie in later as we expanded the crop beds in the future.

I brought the line above ground at various intersections to the crop beds. I installed shut-off valves and 1” PVC sprinkler manifold slip swivel adapters there. The adapters make it easy to reconfigure whatever we use to feed the crop bed.

I attached a Hunter 1" PGV Valve on the other side of the adapter. Which then fed a pressure regulator going to the drip line. I have had a lot of luck with the Hunter sprinkler valves and found them almost indestructible.

Remote Control

The sprinkler valves are ubiquitous; in the US, most of them work off of 24 Volts AC. For now, I ran standard sprinkler cable along the ditches and hooked up the sprinkler values to an OpenSprinkler controller I had lying around from our move. OpenSprinkler is an open-source, web-based smart sprinkler controller created by the amazing Ray Wang.

While this all works well, I want to improve the need to run wires as our crop beds expand. One of the projects on my to-do list is to create a module that can drive the valves, be solar-powered, and communicate wirelessly over 800Mhz LoRa.

Lessons Learned

Our project was not without some teachable moments. This ground in part of Arkansas, at least where we ran the lines, has an interesting consistency when wet that stuck to boots, shovel, and whatever tools you used. So you don’t want to do this job too many times. Oh, and then there are the fire ants.

In some places, I rushed the work; we were dealing with rain, and I wanted to be done. This bit me later. I learned the importance of adequately preparing, cleaning, and cementing PVC connections. Most of all, it allows the solvent to cure before applying pressure.

After having to dig up the leak, I certainly won’t make that mistake again.

"Be Water, My Friend. Empty your mind. Be formless, shapeless, like water. You put water into a cup, it becomes the cup. You put water into a bottle, it becomes the bottle. You put it into a teapot, it becomes the teapot. Now water can flow or it can crash. Be water, my friend."

— Bruce Lee